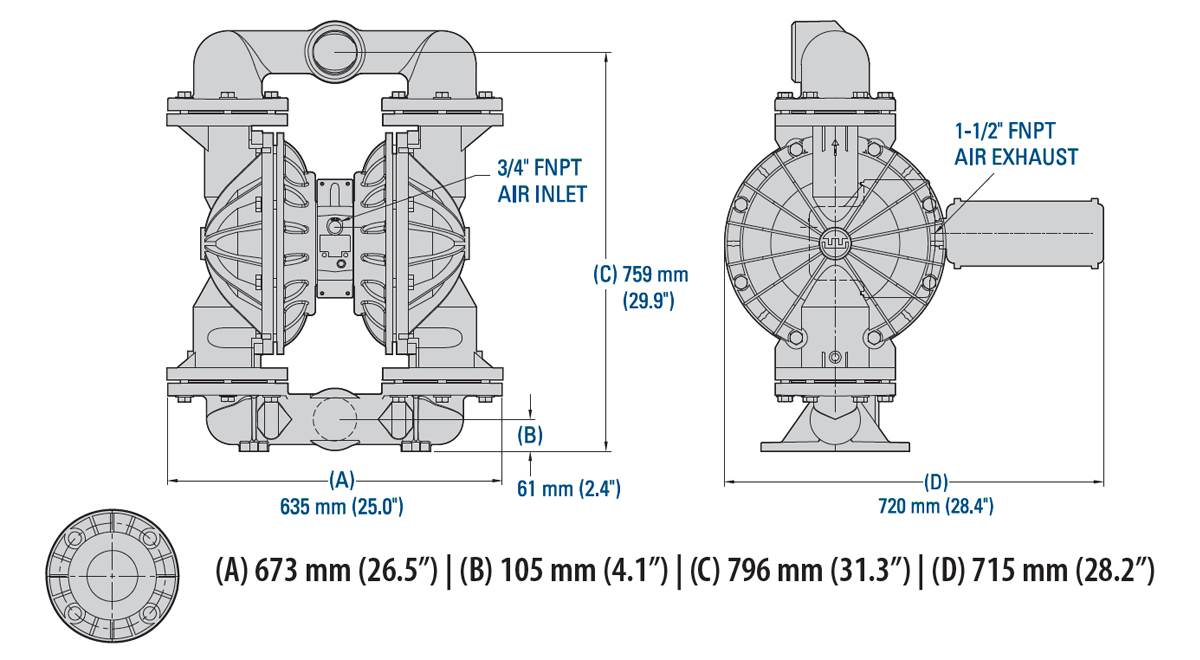

Wilden PS1520/PS1530 Pump 76 mm (3″) Pro-Flo® SHIFT Series Bolted Metal AODD

PS1520/PS1530

Pump Size

3”

Air inlet

3/4” FNPT

Liquid Inlet

3”

Liquid discharge

3”

Connection type

NPT/BSP (Threaded), DIN/ANSI (Flanged)

Max suction lift capacity

Rubber – 5.1 L (1.35 gal), EZ-Install TPE – 5.4 L (1.43 gal), Full-Stroke PTFE – 5.0 L (1.32 gal), Full-Stroke PTFE (Ductile Iron) – 4.8 L (1.26 gal)

Max flow rate

Rubber – 1,026 lpm (271 gpm), EZ-Install TPE – 1,026 lpm (271 gpm), Full-Stroke PTFE – 992 lpm (262 gpm), Full-Stroke PTFE (Ductile Iron) – 874 lpm (231 gpm)

Max pressure

8.6 bar pressure (125 psi)

Max diameter solids

12.7mm

Displacement per stroke

Rubber – 7.2 m (23.8’) Dry, 9.7 m (31.8’) Wet, EZ-Install TPE – 6.4 m (21.1′) Dry, 9.7 m (31.8’) Wet, Full-Stroke PTFE – 6.2 m (20.2′) Dry, 8.6 m (28.4′) Wet, Full-Stroke PTFE (Ductile Iron) – 5.9 m (19.5′) Dry, 9.7 m (31.7′) Wet

Pump Details

The Wilden Pro-flo Shift (PS) is the industry premier air distribution system (ADS) and your ideal solution to increase productivity, lower energy consumption, reduce air consumption and simplicity in maintenance. The design benefits are unmatched by any other ADS on the market. Wildens Pro-flo shift features an air control spool that automatically optimises air consumption and eliminates overfilling of the air chamber with no reduction in flow rate.

Features and benefits of the Pro-Flo SHIFT ADS include:

- Up to 60% in air savings all while retaining existing flow rates

- Reduced total cost of ownership

- Ease of maintenance

- Ability to be used in harsh operating environments

- No electricity required

- Designed off the same basic design principles as the tried and true Pro-Flo Series Unbalanced spool preventing stalling.

- Simple pilot spool to trigger which air chamber is filled

- Minimum moving parts (less wear)

- Tight tolerances to eliminate lost air

GET IN TOUCH